Does one design for functionality, manufacturability or accessibility? This is the traditional argument between the design engineer and the fabrication workshop. Try desoldering 5 or 6 small EMI/RFI shields assembled onto a tiny PCB and the answer to the above would be obvious.

(Case Study)

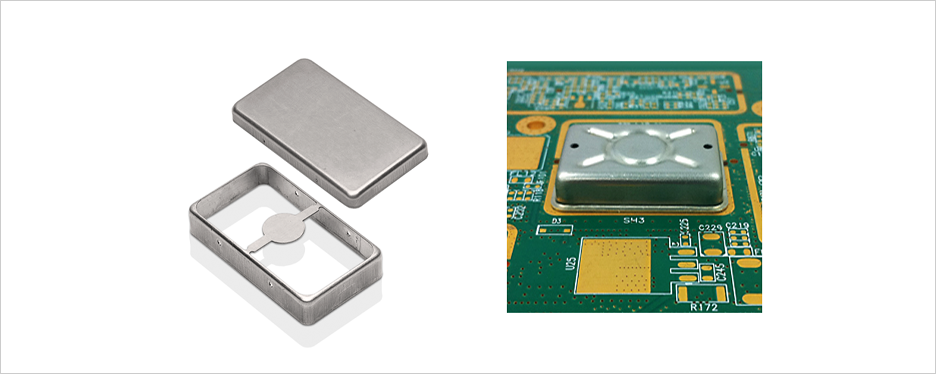

Fig.1 / Fig.2

Two-piece shields (Fig.1), that is a frame soldered to the PCB and a cover which can be snapped on and off easily, are a godsend for field service engineers. Cover Only shields (Fig.2) provide cheap and functional solutions to interference problems, however they may end up becoming an expensive headache. Any repair or rework under the shield requires a messy and expensive solder wicking.

One usually finds these solutions on cheap and proven reliable mass produced circuits, such that when a fault is traced to the area under the shield the solution is simply to replace the print. Conversely, should the print contain expensive components what could be more convenient than flipping off the cover of the shield and replacing once the repair is done.

Two-piece shields are indeed double the cost of a Cover Only, however during assembly they can prove themselves very cost effective. Consider a fully assembled print with a shield ready for reflow. The frame of a Two-piece shield allows the heat to reflow into the circuit area soldering all components within the frame, as well as fixing the frame itself to the circuit.

With Cover Only shields, it is often that components are soldered first, with covers being passed through a secondary reflow. These covers also must have holes (Fig.2) to enable gases to escape during the solder cycle as well as providing access for flushing and cleaning. The simplest and most effective way for snap-on lids are via dimples on the inner side of the cover, seating into respective holes on the frame (Fig.1).

Other solutions are possible, but invariably more expensive. Internal dimension of covers are exactly the same as external dimension of frames, hence the interference of the dimple height provides enough occlusion to create a snug fit.

*Products design and development is certified under ISO 9001 only.