Dedicated three-dimensional laser cutting technology on an existing standard RF shield as a complementary manufacturing station for a shelf product.

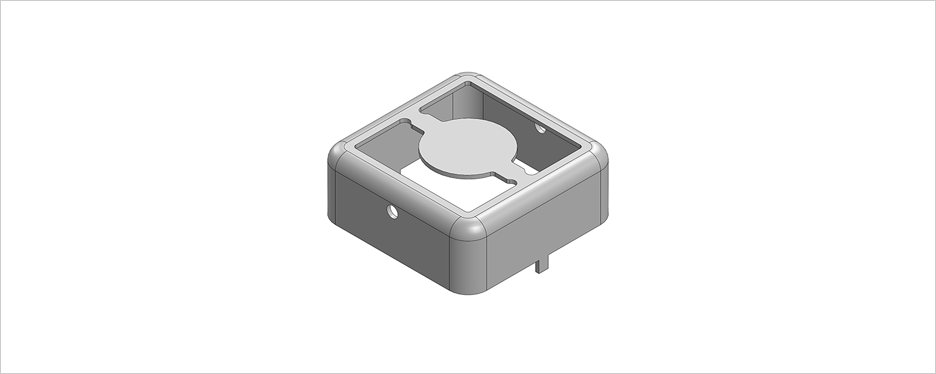

Fig.1

A Telecom company approached us to modify a standard shield to accommodate a circuit edit for a new application they were planning.

The required change involved adding 2.00mm x 1.00mm “mouse-hole” to our MS130-10F standard RF shield Frame to allow routing a PCB trace out of the shielded region on the top layer of the PCB. (Figure 1)

Our Solution

Our proposed solution offered two options:

- For prototyping and small quantities with short delivery times, we added a complementary solution through three-dimensional laser cutting.

- For large production runs, we optimized the custom production with a new design of dedicated progressive die tooling for full production coverage.

What Were The Client’s Concerns?

At first, the client was concerned about how a company that manufactures standard products for international distribution can meet their customizing goals, as such companies are perceived as having low flexibility in adapting to customizing requirements.

However, our accumulated experience and expertise over the years, combined with traditional work methods and advanced, dedicated technologies for customized capabilities, enabled us to offer optimal solutions for these specific requirements.

The client was also concerned about meeting a strict deadline.

In this project, the integration of advanced technology allowed for modifications on standard shields - enabling customization with adherence to short lead times!

Innovation

In this project, we integrated advanced, dedicated three-dimensional laser cutting technology on an existing standard RF shield as a complementary manufacturing station for a shelf product.

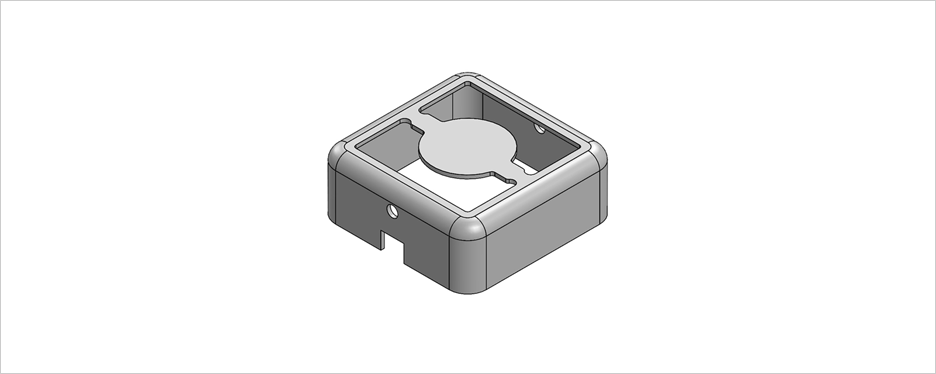

Fig.2

The customer received a unique product according to their requirements, that could only be produced with a dedicated tool without prior investment (NRE) and in short lead times! (Figure 2)

In parallel, a dedicated progressive tool was designed and manufactured for high-volume production runs with full continuous supply according to demand.

If you have any questions or challenges, please don't hesitate to reach out.

*Products design and development is certified under ISO 9001 only.