In today's developing technological world, we are surrounded by devices and technologies that communicate using electromagnetic waves in all areas of life: from personal gadgets and smart homes, through public infrastructure, vehicles, medical products, to military and security, space, and more.

Every day, new products are developed for various uses in diverse environments, with varying configurations, sizes, and frequencies. Consequently, electrical circuit structures are updated, requiring flexible planning of complementary components.

High Precision Laser Cutting

One of the primary advantages of laser cutting in RF shielding is the ability to achieve a high degree of precision when cutting intricate designs with superior accuracy and speed. This precision ensures that RF shields are precisely tailored to fit specific device configurations.

Masach™ engineers can create customized RF shields that cater to the specific needs of diverse industries such as medicine, avionics, and telecommunications. The ability to cut complex shapes and forms provides our customers with the freedom to design RF shields that precisely match device configurations.

This versatility opens new possibilities for shielding designs, accommodating various electronic components, and optimizing their performance while ensuring the highest level of protection from EMI and RFI.

3D Laser Cutting Takes Masach's Drawn-Seamless RF shields to the Next Level

Masach’s diverse range of shelf products allows high flexibility in choosing RF shields based on varying dimensions and materials. In some cases, customers require modifications to these standard shields while maintaining their dimensions.

These customizations might involve mouse holes for conductor passages, varying depths for connector interfaces, ventilation holes for heat dissipation, and other specific needs. Implementing such requirements calls for manufacturing engineering that integrates expertise and experience in jig fabrication, coupled with proficient programming and precise execution of three-dimensional laser cutting for RF applications.

Time-to-market is crucial for the success of electronic devices. Developing custom-designed RF shields often involves time-consuming and costly prototype iterations. Masach has leveraged drawn-seamless RF shields and employed 3D laser cutting to significantly reduce engineering design time. This approach leads to lower costs and accelerated product development cycles.

By utilizing Masach's extensive catalog of drawn-seamless RF shields, engineers can quickly modify their designs to meet specific product requirements, saving valuable time and resources.

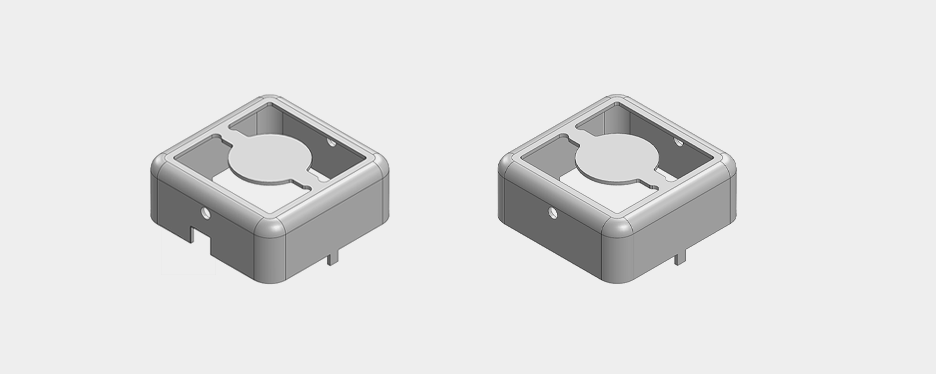

Modified MS130-10F with Mouse Hole / Standard MS130-10F

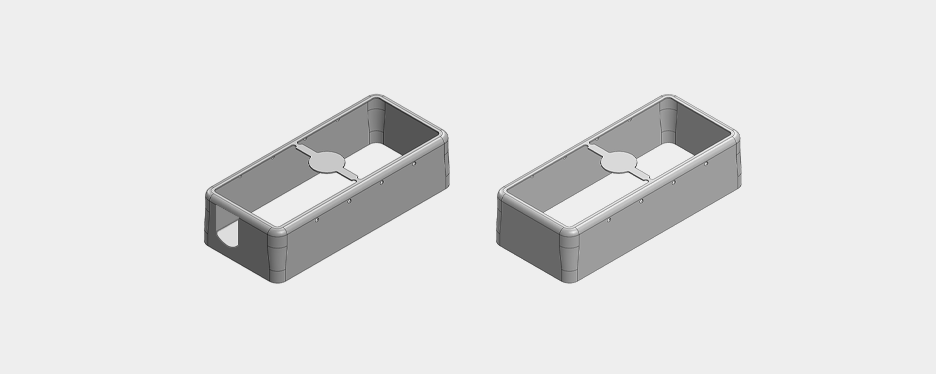

Modified MS544-20F with Connector Interface / Standard MS544-20F

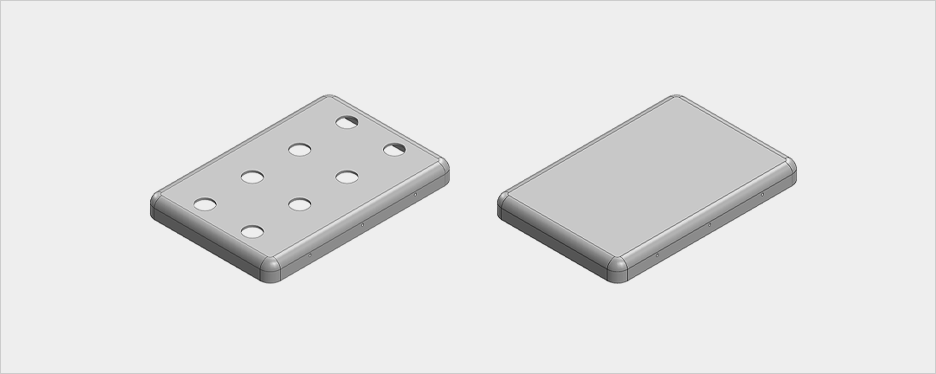

Modified MS345-10CP with Ventilation Holes / Standard MS345-10C

Conclusion: Elevating RF Shield Modifications with 3D Laser Cutting

Masach Tech's innovative approach, combining drawn-seamless RF shields with advanced 3D laser cutting, is transforming the field of RF shield modifications. This synergy ensures a streamlined planning-to-production process, reducing costs, engineering design time, and turnaround times.

As a leader in board-level RF shielding for passive components, we are dedicated to meeting the ever-evolving needs of industries. Our commitment to innovation is reflected in our constant investments in new technologies and production methods, ensuring that our products remain relevant in an electronics world that is constantly evolving.

With Masach Tech 3D laser cutting, you can:

- Improve existing RF shields: Adjust standard shields to meet specific component and heat dissipation needs without changing their essential dimensions.

- Create custom solutions: Design detailed custom shapes, accurate cutouts, and ventilation holes that align with your specific design requirements.

- High precision and accuracy: Our state-of-the-art laser technology offers meticulous control for consistent and reliable quality results.

- Broad material compatibility: Our process is compatible with various RF shield materials, including copper, aluminum, nickel-silver, and tin-plated steel.

- Efficient workflow and quick delivery: Our streamlined process guarantees prompt delivery of custom shielding solutions.

Take your RF challenges to the next level with Masach Tech's 3D laser cutting, toward achieving exceptional shielding performance and realizing your design's full potential.

Contact Us to discuss your desired outcomes and discover the latest in RF shielding.

*Products design and development is certified under ISO 9001 only.